We’d like to showcase our 330-ton Seyi press with servo technology, it has a bed size of just over 100 inches in length. This is one of our 26 stamping presses within our facility. This press is unique to the fleet because of it’s ability to stamp a wide variety of material with high precision and speeds while using less energy. We’ve paired the servo technology this press offers with a nut insertion machine (pictured in the lower right corner) to maximize efficiency. This machine automatically feeds nuts into the stamping die and fastens them into the stamped metal component allowing us to offer an incredibly competitive solution for our customers.

You May Also Like

The flexibility you need from a supplier – Ensuring your Metal Parts needs are met!

Your 24/7 Metal Stamping Solution In times like these, you need a vendor you can trust – but also one…

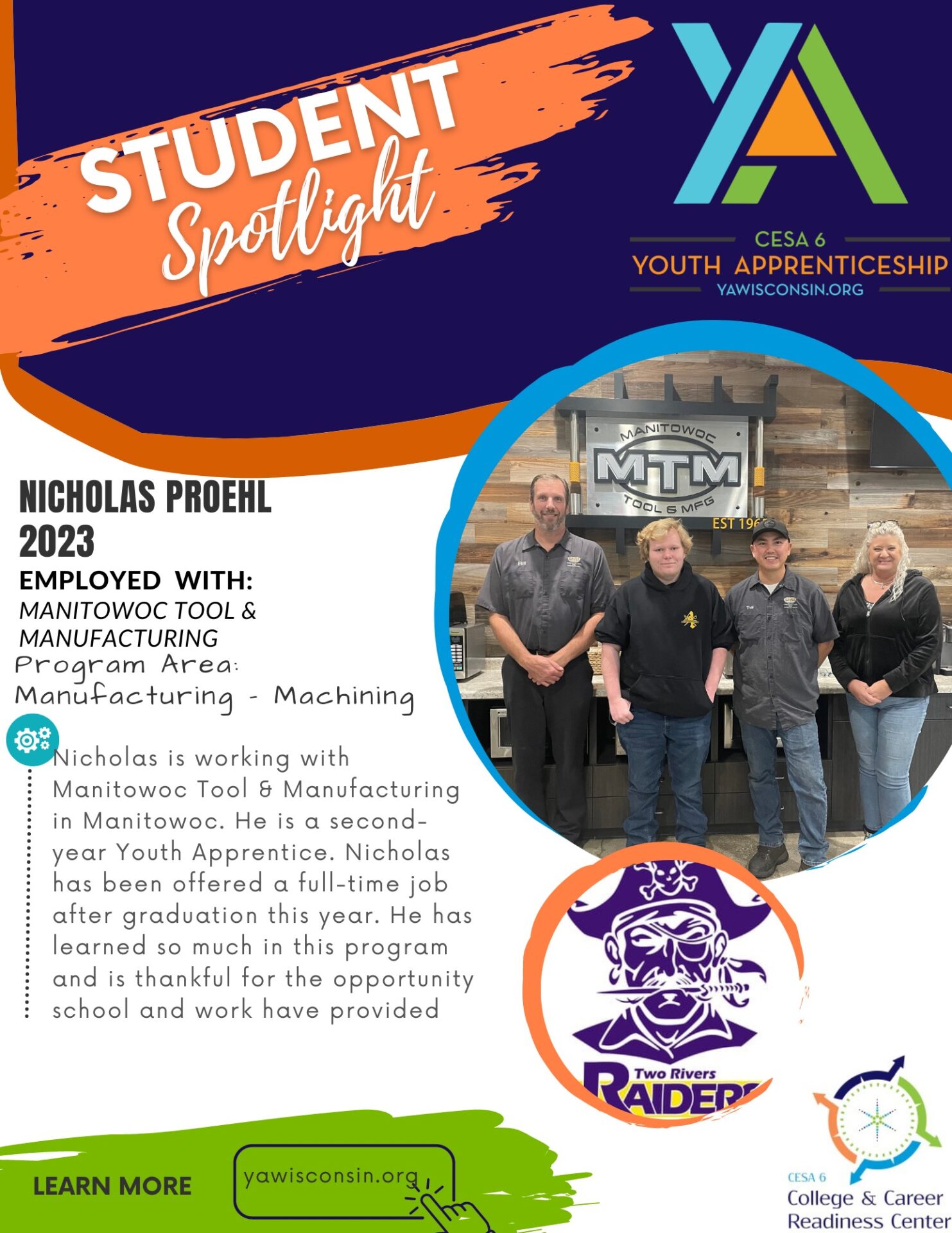

Celebrating one of our Youth Apprentices

Here at Manitowoc Tool, we are grateful for the relationships and opportunities created via our Apprenticeship/YA Program. Thanks for your…

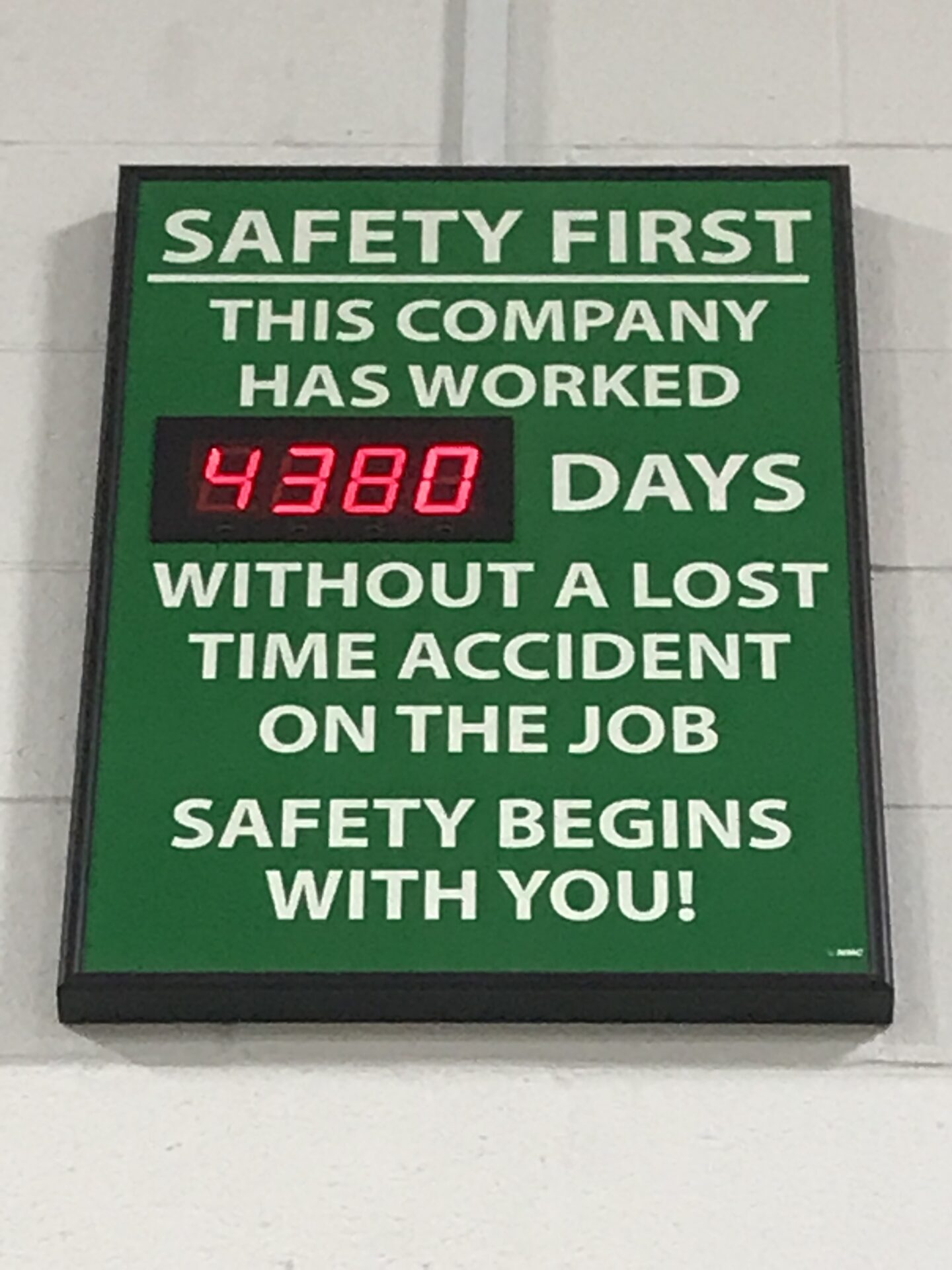

12-YEARS at MTM Without a Lost-Time Accident

— Safety is Our Priority — Today marks 12-years WITHOUT A LOST TIME ACCIDENT at Manitowoc Tool & Manufacturing ,…

Another Year Safer – 11 Year Safety Record

Today, February 13th, 2018, marks 4,015 Days (11-Years) at Manitowoc Tool and Manufacturing, LLC Without A Lost-Time Accident, a record…