What we do

Turnkey Operations

- Production Stamping

- Metal Fabrication

- Prototype Machining

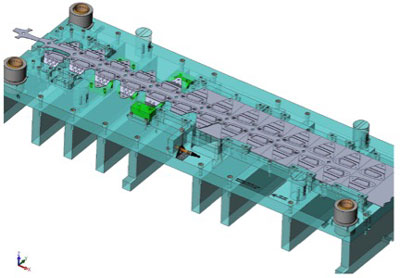

- Tool & Die Making

- Stamping Dies

- Prototype Stampings

- Casting Trim Dies

- Complete Fabrications

- Fixtures/Gages

- Assembly

- Spot Welding

- Robotic Welding

- Production Machining (CNC)

- Surface/Blanchard Grinding

- Fiber Optic Laser, WaterJet and Wire EDM Cutting

Secondary Operations

- Paint

- Clinch Nut Staking

- E-Coating

- Heat Treating

- Plating

- Press Brake

Capacity

- 3-Shifts/7 days a week both in Stamping Department and Tool & Die Department.

- Press Capacities: 100 to 1100 Tons

- 35,000 lb Lifting Capacity

- 250,000 square feet of climate-controlled manufacturing facility

- MTM has its own fleet of trucks for delivery

Equipment List

Production: 28 Stamping Presses (100 tons to 1100 tons)

Wire EDM: 3 Wire EDM’s to support tool & die shop

WaterJet: Capabilities to cut up to 8 inch thick material

Fiber Optic Laser: Capabilities to cut sheet steel 120″x60″ and up to 1″ thick

Assembly Equipment & Fixtures: Full assembly capabilities to handle small projects through high volume complex assembled units

Welding: Spot Welding & Robotic Welding capability

Production Part Washer: Capable of producing parts to any cleanliness specification

Surface/Blanchard Grinding: Large grinders to accommodate various sized stamping dies

CNC Mills/Lathes: Various automated CNC equipment to support tool & die shop

Presses

Quality Lab

At Manitowoc Tool & Manufacturing, we invest highly in the latest & greatest of Quality Control & Testing Equipment. You can count on us to provide all quality documentation, promptly and accurately. We are committed to providing superior service, on-time deliveries, and a quality product. Continuous improvement of our processes and strong communication throughout our organization with an emphasis on customer satisfaction is our ultimate goal.

- APQP Process Controls

- Full PPAP Capabilities to Current AIAG Standards and Automotive Expectations

- Electronically Stored Inspection Data at All Phases of Production

- Automated Calibration System

- Corrective Action Process Following 8D format with 5Y Analysis

- Preventative Action Systems (5S, EPIC – Expo Process Improvement Committee, Safety Committee)

- Shop Floor Digital KPI Displays

- Supply Chain Management Program

Precision. Quality.

In-house Engineering Department for Die and Fixture Design

Utilizing the following software:

- Pro/E Tool & Fixture Design

- Autocad

- IronCad

- SolidWorks/Logo Press

- Forming Analysis and Flat Blank Prediction Software

- Mastercam

- GibbsCAM

Typical Customer Profile

1,000 to 3,000,000 Estimated Annual Usages along with value-added requirements.

Additional Services

- CMI (Customer Maintained Inventories) Internal and External

- KANBAN Capable

- EDI Capable

- Cost Reduction Engineer on Staff